- Knitting Series

- Tatting series

- Towel Series

- Digital Series

Knitting Series

» Home » ProductsNew generation of high efficiency,energy-saving and intellective rope washing unit

It took 3 years lunching program and finally developed and introduced a new generation of high efficiency, energy saves, smart rope was hing unit.

hing unit.

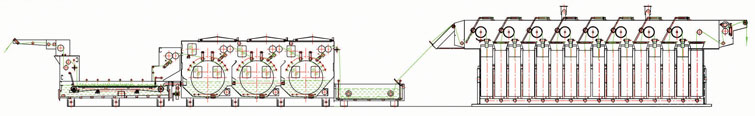

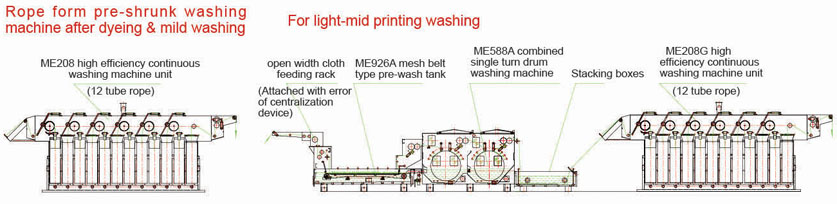

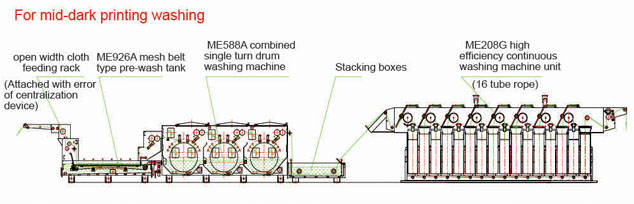

With a modular design, each of the four groups of tanks for a module can be individually dyed washing or pre-shrunk after washing, washing process, can also be combined with flat pieces of dumping and drum washing, for efficient washing after printing, can be combined for different process requirements flexible, and optimal configuration.

Can meet the washing requirements for various fabric (full cotton, and cotton ammonia, and fiber, and cashmere class, grams heavy range 80-600GSM) of various washed technology, particularly in the after dyeing and after printing of washed technology, greatly savings in water and steam energy consumption cost, while to more quality of equipment structure and design, provide strong support to customers participating in market competition.

|

|

ME208 High efficiency, energy-saving washing machine and intellective rope washing unit |

Old type open segmented rope washing machine |

|

water consumption |

|

|

|

Cotton/Cotton reactive dye printing |

12 tons/ton |

40 tons/ton |

|

Heavy velvet decentralized printing |

20 tons/ton |

60 tons/ton |

|

Steam consumption |

|

|

|

Cotton/Cotton reactive dye printing |

1.2 tons/ton |

4 tons/ton |

|

Heavy velvet decentralized printing |

1.6 tons/ton |

6 tons/ton |

| Measured by the output of 20 tons per day: save 500-800 tons of water a day, about 60 tons of steam | ||

|

|

|

| Translation type low tension centering stepping forward system | Open width loosing stacked immersion unit | |

|

Adjustable double-wire stentering systems, combined with banner pan in the infrared; ensure the fabric is centered under low tension into the cloth, without pulling distortion. |

By dumping and large capacity circulating spray 3-8 minutes, floating color and paste fully expanding, dynamic filtering system will filter out impurities and wash down hairiness, greatly improve water reuse. |

|

|

|

|

| Open width efficient spraying drum unit | Rope form full closed high efficiency washing unit | |

|

Fabric is on the punching drum, 6 wets penetration washing, high efficiency, no damage, water pressure can be adjusted, with separate filter systems, to improve the reuse of water. |

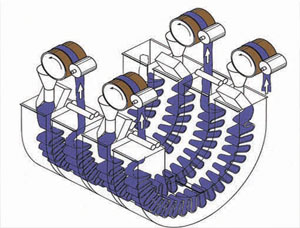

"U"-Stacking type immersing, each tank is equipped with a separate sprinkler system and rolling cart system, at the same time with separate filter systems, amount per slot capacity adjustable (30M-150M), to accommodate a 80-600 g/square meter weight of fabric, 8 slots, 12 slots and 16 slots can be optional water. |

|

|

|

|

Fabric "U" running route, equipped with rolling padder and spray nozzle, saving space, big fabric stocking volume capacity. |

With position limitation and anti-wrapped cloth rope rolling padder system, out of rolling paddert equipped with ring-shaped spray. |

|

|

|

||

|

Each washing tank has independent filtration systems, for both heating and reuse ofwater. |

Located at the center of the washing machine with independent filter system, good for water reuse. |

Drain valve in the pneumatic set is located at the side of the washing machine, without having to do complex foundation. |

Performance comparison

1.Fully enclosed design, no extra steam outflow, greatly reduces the waste of steam, at the same time improving the working environment.

Traditional rope washing machine is open, a lot of steam leaking waste is extremely serious, workshop large mist, and working conditions are poor.

2.Use the design of open-width pre-washing, by stacking puffing, a large flow of circulating spray, full floating color wash and paste, will loopback to the water tank after filtering impurities and hairiness, greatly improve water reuse.

Traditional rope washing machines are a leading roll immersion for a short time, puffing is not sufficient, and pre-wash led rope washing uneven, incomplete ,and because there is no filtration system, you must add a lot of water is used to dilute wash trough concentrations, resulting in large numbers of wasted water.

3.Rope form washing progress uses independent temperature control; fabric stock volume (20-150 m) can be set independently. With separate circular spray (30 ton/hour) and filtration system, greatly improving the liquid exchange frequency, thus improving the washing effect.

And the volume of traditional rope capacity washing machine out of control, simply by soaking washing and rolling, fluid exchange fewer rolling car led cloth bruised too much pressure; it cannot meet the high customer quality products.

4.Spacing saving: total length 24 m, installation flexibility, "u" or "L"-shaped installation, without any complex anchor base.

Traditional rope washing machine is about 38 meters, need complex anchor base, high costs and workload.

5.With full automatic computer control, no bounding, and no blocking; the machine only needs 1-2 operators, smart, simple operation.

Traditional rope washing machine just rely on each slot manual fine tuning, caused parking easy to plug, wrap cloth, often need to pull by hand, workers operating strength and danger, you typically need 3-5 people continuing inspection operation.

6.Equipped with automatic feeding system, process is accurate and stable, good repetition.

Traditional rope washing machine just rely on manual feed, additive concentration fluctuations, unstable washes, fluctuations in the product quality.

Tel:+86-510-86518888

Office:+86-510-86505888

Fax:+86-510-86503888

Tel:+86-13961612888

P.C.:214401

Website:www.foundmach.com

www.foundmach.com.cn

Email:Steven@found-machine.com

In this announcement, the process flow, as well as specifications and parameters, may be different from the actual products. It's intended to prevent unfair competition and theft of trade secrets. If you are interested in our products, please call 0510-86518888 to ask for product details! Waiting for good news.