- Knitting Series

- Tatting series

- Towel Series

- Digital Series

Tatting series

» Home » ProductsIntellectual Energy-Saving Long Loop Steam Ager

1.ApplicationThe machine is used to color-fix and bake for the fiber after being dyed, it applies for synthetic fiber, chemical fiber, knitted fabrics and non-woven fabrics. Also many kinds of dyestuffs are applicable, the weight of

per m2 for the fabrics should be form 50 g/m2 to 450 m2.

per m2 for the fabrics should be form 50 g/m2 to 450 m2.2.Main technical parameters

1. Working side: (left / right) hand drive facing inlet end.

2. Working width: 1800 mm-3600 mm

3. Inlet / outlet mode of fabrics: the inlet and outlet is separately set on the front and rear of machine or the same side. It is suitable for: single-web single layer, double-web double layer.

4. Capacity: 140 m, 210 m, 280 m, 350 m, 420 m

5. Loop length: 1.25 m-2.5 m, adjust proportion: 1:2

6. Speed: 5 m/min-50m/min

7. Applied products: knitting fabrics and tatting fabrics

8. The minimum steam pressure: 0.3 mpa

9. The highest supplied water temperature: 60?

10. To be suitable for following dyestuff, reactive dyestuff, high temperature and low temperature dyeing.

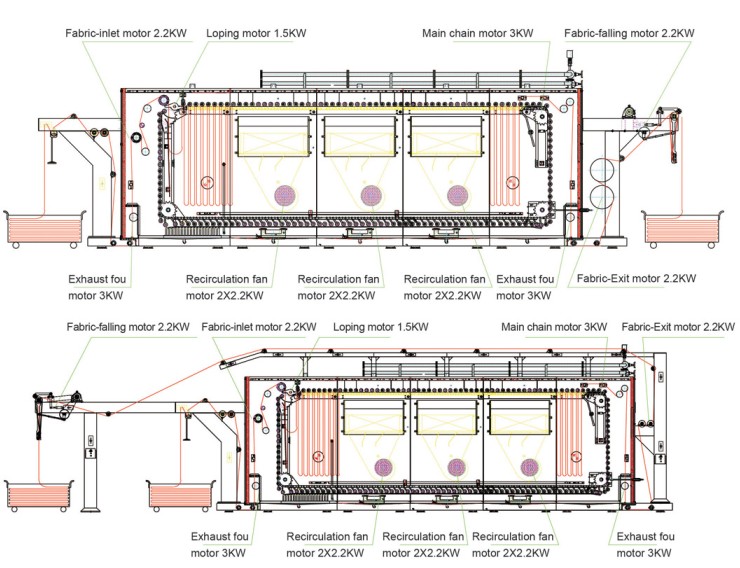

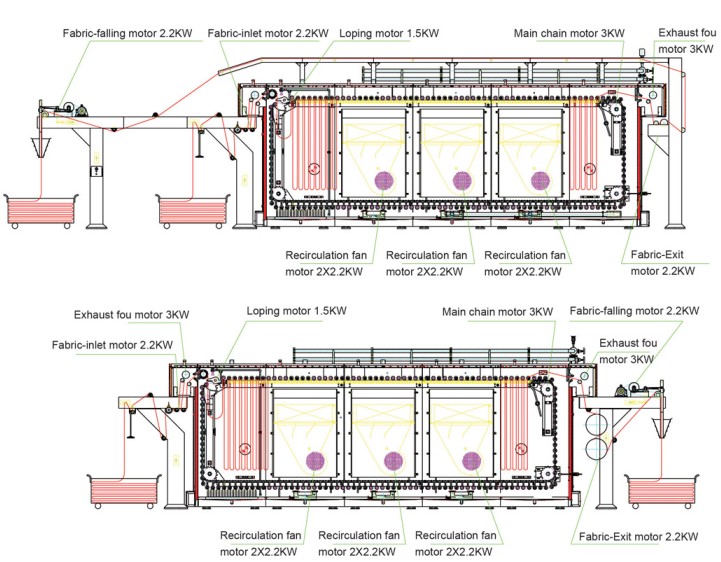

3. Machine construction

1. Inlet frame: fabrics inlet frame, tighten frame, fraction roller, guild roller.

2. Main steaming chamber: includes entry locks, entry and exit sections of steamer and several intermediate sections (fabric capacity of each 70 m, with 2 recirculation fans, 2 heat exchangers, 2 injections of moisture). Heated roof, bottom heating pipe, viewing windows with lighting fittings, looping entry roller, looping device, chain guide tracks, supporting rod, main drive, fabric

exit speed regulator with detecting device for fabric capacity, exit locks and exhaust fan, etc.

3. Moisturizing device:consisting of high-pressure pump, high-pressure water storage,electric controlling valve, temperature probe and mixed injector. The humidity in the steaming chamber could be controlled according to craft.

4. Saturator: Special designed Saturator asks no external steam,which greatly reduces the steam consumption of the whole steamer.

5. Oil circulation heating system: mainly includes hot heater and seamless tubular steel for connecting.

6. A set of moisture temperature system: The middle section of the loop ager used in oil circulation heating system. Mainly including temperature adjustment device, temperature controlling and measuring device, electric three-way valve.

7. A set of pipe fittings: To be used in the middle section of the steamer.Consisting of: stop valves in front of and behind the regulator valve in supply pipe, stop valve in return pipe, draining valves, venting valves.

8. Power supply cabinet: consisting of PLC, interface operating screen, AC frequency converter, main switch and buttons.

9. AC motor drive: consisting of PLC,synchronizer, switching and controlling device, controlling cabinet, etc.

10. Wiring material for the entire range.

11. Fabric exit scaffold:

Mainly including: fabric exit frameworks, traction rollers, guild rollers, fabric falling lorry, mechanical drive, etc. to be suitable for single-web single layer operation, single-web double layer operation, double-web single layer operation, double-web double layer operation. Consumers can select suitable ways according to the condition.

12. According to the supplier's flow chart and wire routing map.

4.Customer self-preparing parts

1. Oil circulation boiler: produce 500 thousand per hour.

2. Necessary amount of heat transfer oil.

3. The pipes and valves that used for re-heating the transfer oil.

5.Installation and debugging

1. The levelness of the combination with chamber bottom and wall board: vertically no more than 3 mm, horizontally no more than 1 mm.

2. Wall boards verticality windage no more than 3 mm.

3. Wall boards catercorner windage no more than 5 mm.

4. Levelness of carrying roller in lead rail no more than �3 mm.

5. Levelness of chain guide tracks no more than �3 mm.

6. Verticality of supporting rod' chain wheel no more than �3 mm.

7. Levelness of supporting rod' chain wheel no more than rod �3 mm

8. Transmission shaft and guild roller's parallelism should be no more than � 2 mm.

9. Capacity adjusting device should turn flexible, detect probe should be ingenious, recirculation fan should run steadily.

10. When the carrying roller with fabric loop on it, it should be ingenious, recirculation fan should run steadily.

6.The main characteristic and advantages of the machine

A . Machinery

1. The chamber is made of 4 mm 09CuPNiCr-A anti-climate sheet, (also can be made of special steel according to customer's desire), and coated with special anticorrosive coating which makes it prolong the service time.

2. The main chains are made of 40Cr heat treated alloy steel therefore more rigid and durable and with less deformation and elongation; also the chains are galvanized which makes the service life longer.

3. Unique and reliable manipulator looping device compare to the similar steamer, it has no chain broken problem, no carting rod strike problem??and no need to cool the chamber when repairing, it can work to the speed of 50 m/min and the capacity will be 20% more than the average ones.

4. The circulation of the steam in the chamber: the steam supply pipelines, impeller of the fan, guide plate etc. are all made of 09CuPNiCr-A anti-climate steel sheet (Also can be made of special stainless steel according to customer's desire which is more anticorrosive and with longer service tlme.

5. The carrying rod inside the chamber is the 50 mm diametral roller, which is very light, firm, they rotate in their orbit, which avoids the crosspiece marks.

6. Unique humidifying device, which can be taken down without stopping the machine, after cleaning the feculence blocks in the nozzle, it can revert easily without any influence of production also can be guaranteed of the quality.

|

|

|

||

B. Humidifying craft and temperature control

1. There are a special exhaling device in the looping place to damp the fabrics, thus makes the color generating more sufficiently, the looping more stably, also can clear up the static.

2. One meter blow the looping place, there is a jetting device supplies big amount of saturated steam, which ensure the color of the fabrics more sufficiently and vividly.

3. Easily set and taken-down damping device give the constant water pressure under the frequency control foggy steam ejects from the four nozzles into the chamber well-proportionally by the donkey steam and circulation of the fans, and control the temperature and humidity in chamber.

4. The steamer has several temperature measuring points (according to the capacity: each side a measuring point above the air ducts.

D. Technological adaptability

1. Disperse process: each room with independent temperature control system, each room's constant temperature is stable with a very small temperature difference; the normal temperature of a disperse process is � 1 ? unique wetting apparatus and humidification devices for each room make the colors more bright; conducting oil heating way and reasonable radiator design (rolling chip) make it more speedy and energy-saving heating for the machine.

2. Active process: based on allocation of spread process with content began to play its major characteristics. The steam with maximum moisture content in faster and closest way through the circle of fans even enter the steam box, enabling full absorption of the fabric in the syeam box, also heating release at the meantime, in the course of exothermic, the temperature of steam box rising. At this moment, number of measurement points startup humidification devices. Then ultra-fine and a lot of fans will be the role of aerosol in the next cycle to add to the steam box. This action both balances of the process of setting a constant temperature and also remains major humidity in steam box to make cloth put color on fully and pattern bright.

3. Carving process: wlth a constant humidity and stable temperature, through a unique mechanical design and continuous improvement, Abe made a breskthrough in steaming machine caring machine steaming only foreign to the stability of processing bottlenecks, regardless of truly single-rate processing, carving out a flower type: edges and corners clear, full flower, color fidelity, there?adimensional sense, practice has proved of stability and constant quality, but also to achieve even more than the imported steaming machine.

(note: welcome customers to visit the factory)

E. Energy-saving emission reduction

1. The below-fabric inlet and outlet design makes the spare and the exhaust gas overbrims the chamber from up to bottom, which makes full use of the saturated steam and save the steam, compare to the primary above-fabric inlet and outlet design, the new design saves 16.7% steam. (the primary machine type use 1~1.2 ton/hour, the new type uses 0.8~1 ton/hour)

2. The unique saturated steam generator works this way: the hot water feeds from heat-conducting oil plate to heat-conducting oil pipe, then generate the sufficient moist saturated steam to supply the steamer. As the heat-conducting oil is recycling, every saturated steam generator only needs the heat of 45000 therm to work, which needs 31.5% less steam than the similar machine that directly uses the steam (the primary machine type uses 0.8~1 ton/hour, the new type uses 0.55~0.7 ton/hour).

|

|

|

|

|

||

|

|

Tel:+86-510-86518888

Office:+86-510-86505888

Fax:+86-510-86503888

Tel:+86-13961612888

P.C.:214401

Website:www.foundmach.com

www.foundmach.com.cn

Email:Steven@found-machine.com

In this announcement, the process flow, as well as specifications and parameters, may be different from the actual products. It's intended to prevent unfair competition and theft of trade secrets. If you are interested in our products, please call 0510-86518888 to ask for product details! Waiting for good news.